There are many instances where people have used the words PEX fittings, as well as Polybutylene, and pipe nearly in the same way, as if they were one and similar. Can i use pex fittings on polybutylene pipe??

One of the first things must be mindful of is the fact that pex pipes and PB fittings differ. It is the most important question to ask whether PEX fittings can be utilized on pipes from PB after all.

Can I use PEX fittings on replace polybutylene pipe?

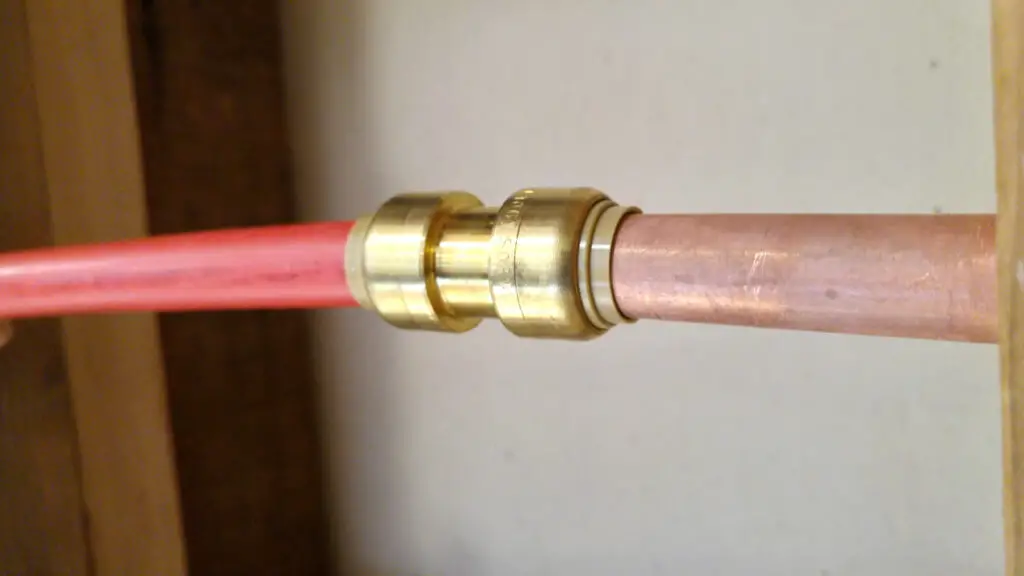

To use PEX to connect pipe and vice versa, transition couplings must be utilized. In the absence of copper or brass crimp rings that have transition couplings The polybutene pipe connection is always wider in its the diameter. One thing that is common between the two pipes is they’re both made of plastic.

It is essential to be aware that despite being made from the same materials, PEX tubing and polyethylene fittings differ quite a bit. While both are made of plastic they’re not manufactured in the same manner.

Additionally, PEX fitting can only be used on polyethylene using the aid of the converter. It functions in the form of a ring which assists to make the change. Without it, one fitting won’t be inserted into the next fitting.

In addition, it is also necessary to insert crimp and Crimping equipment to ensure connections. Making sure you measure and mark the depth of insertion is crucial for this procedure.

Will fittings work on polybutylene pipes?

If you try to install PEX to fit polyethylene on a line on its own, it’s not likely it would be successful. It is because Polybutylene is a lot thinner than PEX.

So, even if put an pex pipes fits in polybutylene, it will not work in terms of dimensions. The two shark bite fittings can have a different proportion as well as one to be less tight than the one.

To do this, the fittings should be joined by a transition ring, or coupling.

3 reasons why you can use fittings on polybutylene:

It is possible to fittings for polyethylene pipe with certain modifications, as well as adding additional connectors. There are other advantages of using PEX for polybutylene piping:

Both are plastic fitting:

One of the primary reason why many believe that pex pipes as well as PB fittings can be compatible is due to the plastic base they’re made from.

They are what differentiate them from copper pipes, and it is yet another reason they’re able to work with one another.

Use of connector:

While the fittings may not be the same and loosen when the fitting is inserted to replace the PEX fitting in the polybutylene. Connectors allow to join the fittings.

Best of both:

Because PEX come with a couple of advantages when compared to pb fitting as well. PB pipe fittings possess some benefits over PEX, when connected to the fittings together, you can take advantage of the advantages of each plumbing system.

Are PEX and polybutylene fittings the same?

In the case of sharkbite connector or transitions One of the most frequently asked concerns frequently asked is whether pex pipes and fittings made from polybutylene are identical.

There is a confusion due to reasons that both pex pipes along with polybutylene, are the same size both made of plastic. Both piping types have been responsible for replacing all pipe fittings for homes which were copper pipes.

One of the main differentiators between the two is that PEX pipes are cross-linked by a polymer chains, which isn’t as prevalent in Polyethylene and PB pipes.

PEX pipes, for example, can handle a higher tension than pipes made of polybutylene due to of how the polymer has been cross-linked. It is the reason many houses compression are commonly used for areas that need to face extreme pressure water flows or leaks.

PEX are also a better choice when you plan to get a pump that can handle extremely hot water heater. Because pex pipes is far more resilient to heat, it is not likely to melt at all. Polybutylene or pb fitting however, may possess more resistance to corrosion because of its structure-based bonding.

Because of similar problems with chloramine, PEX plumbing fittings can leak and get weaker over a prolonged duration. Be aware this: in United States, pex piping were chosen ahead of PB which is prohibited within the USA.

PB also comes with a higher oxygen barrier. Likewise, a pex piping are more permeable too. Since pex pipes is extremely permeable it can cause a variety of difficulties when it is used for fittings. In general, pex connection are different from fittings for replace pipe because of differences in technology.

How do you connect polybutylene to PEX?

A lot of people don’t want to pay for the cost of plumbing, which could be very high depending upon the location and house you live in.

While these plumbing tasks should be left to specialists, but if you’re among those who want to use these fitting Here are some basic steps to assist you to do it:

Choose the right connector:

The initial step for joining polybutylene and pex tubing by transition is selecting the correct connector.

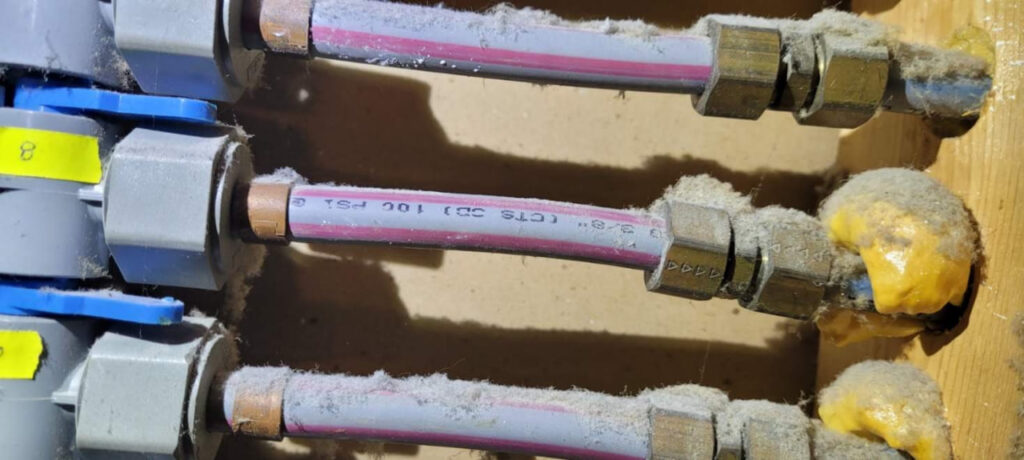

It’s up to you to decide based on which pipe is used. If you are using polybutylene or PEX The only transition collars suitable for metal pipe include collar colors of grey and tan, respectively.

Remember that white collar don’t work with both, but will only work with PVC.

Give a clean cut to the pipe:

This is the next crucial step in which you will need to make a clear cut into the wall for the metal pipe. When you do this, you might want to take precise measurements and the necessary measurements, if you want.

Be careful not to scratch the pipe using the scale tool as well as other tools that you might employ. It is possible to use either automatic or semi-automatic cutters for cutting the pipe in the most neat method.

Measuring the insertion depth:

Following that, the challenging part is taking measurements of the depth at which you insert.

Transition fitting that push-to connect offer the manufacturer a range of insertion depths and, depending on that, the dimension of fitting vary. As an example, if you have one fitting of size 1 inch (2.54 cm), you could anticipate an insertion depth within the pipe that is around 1.31 inches (3.33 cm).

When you have measured the pipe, trace the location within the pipe. It is recommended to make use of a gauge during this procedure, or else marking and measuring the pipe’s depth can be difficult.

Insert the connector and adjust accordingly:

The next steps are simple. The fitting that you’ve picked will fit through both pipes depending on the size of insertion. Connect the fitting and make adjustments as needed.

One of the main advantages to the fitting you use is that you do not need to worry about losing any of the time that is required to fill in but only if you’ve taken the proper measurements for your insertion.

Run the water:

Then, you can take the hot water heater and run it a couple of times to see for loose connections.

Final Thoughts

It is possible to use compression fittings to connect polyethylene pipes however you will require connecting it with the aid of rings. The transition coupling is the sole option to connect these fittings because they’re distinct in their dimensions. Two plastic compression fittings may also serve instead of other.

Hey! I’m Leanda Bailey. I’m here to explain every plumbing installation and repair you may have in your kitchen or bathroom. Also, I’ll try to find you the best products on the market for your plumbing work.